In today’s fast-paced world, the manufacturing landscape is undergoing a remarkable transformation fueled by technological advancements. At the forefront of this revolution lies automation, a key driver reshaping how goods are produced across industries. Let’s dive into the intricacies of automation in manufacturing and explore its multifaceted impact, from enhancing productivity to shaping the future of work.

Understanding Automation in Manufacturing

Automation in manufacturing refers to integrating technologies and systems to perform tasks traditionally carried out by humans. These technologies range from robotics and computer numerical control (CNC) machines to sophisticated software algorithms. The overarching goal of automation is to streamline processes, optimize efficiency, and minimize human intervention.

Types of Automation Systems

Automation systems in manufacturing can be categorized into various types based on their functionality and scope. These include:

- Fixed automation: Designed for repetitive tasks with little variation, such as assembly line operations.

- Flexible automation: Adaptable systems capable of handling diverse tasks and product variations.

- Programmable automation: Configurable systems that can perform different tasks based on specific instructions.

Advantages of Automation

The adoption of automation in manufacturing offers a myriad of benefits that contribute to operational excellence and competitive advantage.

Increased Productivity and Efficiency

Automation accelerates production cycles by streamlining workflows and reducing cycle times. Tasks that once required hours of manual labor can now be completed in minutes, boosting overall productivity and output.

Improved Quality Control

Automation minimizes human error and variability, leading to consistent product quality and adherence to stringent standards. Through precise control and monitoring, manufacturers can identify defects early in the production process, ensuring that only flawless products reach the market.

Cost Savings and Reduced Waste

While the initial investment in automation technology may be substantial, the long-term cost savings are significant. By minimizing labor costs, optimizing resource utilization, and reducing scrap and rework, manufacturers can achieve substantial cost efficiencies over time.

Enhanced Safety for Workers

Automation mitigates occupational hazards by automating high-risk tasks and creating safer working environments for employees. By minimizing direct human involvement in hazardous operations, manufacturers can prevent workplace injuries and promote employee well-being.

Applications of Automation in Manufacturing

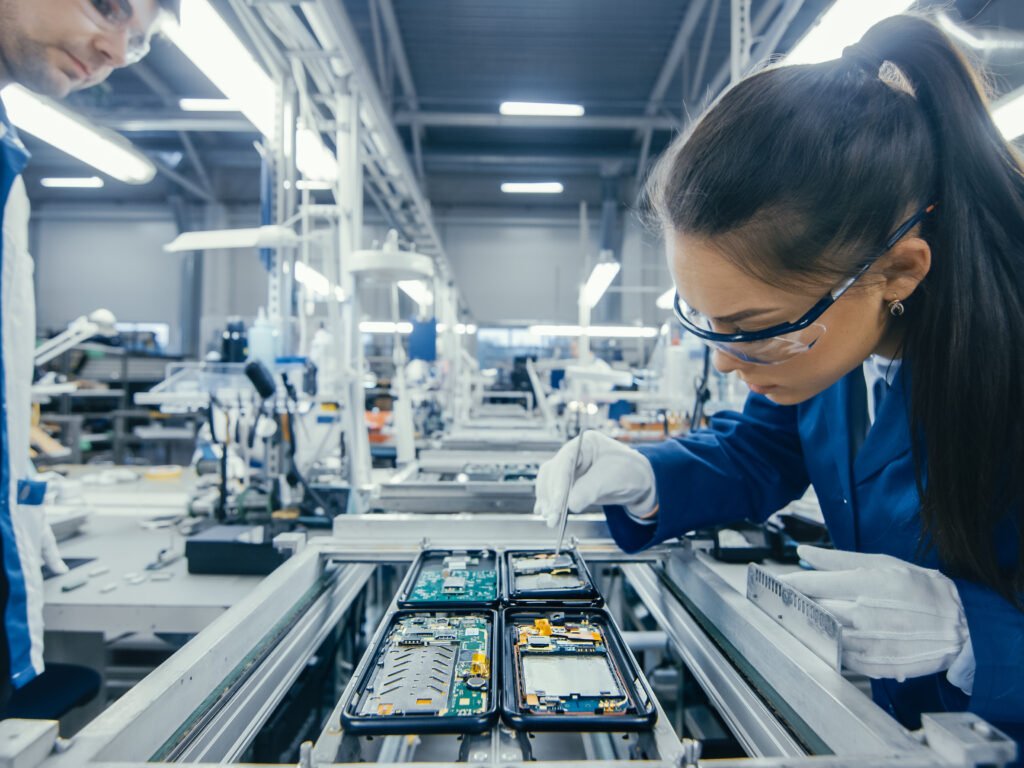

Automation technologies find application across a wide spectrum of manufacturing processes, revolutionizing how goods are produced and assembled.

Robotics and Robotic Arms

Robotic systems equipped with advanced sensors and actuators perform various tasks, including material handling, welding, and painting, with unparalleled precision and speed. Collaborative robots, or cobots, work alongside human operators, enhancing efficiency and flexibility on the factory floor.

Automated Assembly Lines

In automated assembly lines, robots equipped with specialized end-effectors, such as grippers (What is a gripper?), perform intricate tasks with precision and dexterity. A gripper is a mechanical device designed to grasp, hold, and manipulate objects during the manufacturing process.

Computer Numerical Control (CNC) Machines

CNC machines utilise computer-controlled systems to fabricate intricate components with unparalleled accuracy and repeatability. From milling and turning to laser cutting and 3D printing, CNC machines play a pivotal role in modern manufacturing across diverse industries.

Automated Material Handling Systems

Automated material handling systems transport raw materials, work-in-progress components, and finished goods throughout the manufacturing facility with precision and efficiency. Automated guided vehicles (AGVs) and conveyor systems optimize material flow, minimize lead times, and reduce manual handling efforts.

Challenges and Considerations

Despite its transformative potential, the adoption of automation in manufacturing poses several challenges and considerations that warrant careful attention.

Initial Investment Costs

The upfront costs associated with acquiring and implementing automation technologies can be prohibitive for small and medium-sized manufacturers. From capital expenditures to integration and training expenses, the total cost of ownership must be carefully evaluated to justify the investment in automation.

Workforce Training and Adaptation

The transition to automated manufacturing environments necessitates upskilling and reskilling of the workforce to operate and maintain complex automation systems effectively. Training programs and knowledge transfer initiatives are essential to equip employees with the skills and competencies required in the digital age.

Maintenance and Troubleshooting

Automation systems require regular maintenance and troubleshooting to ensure optimal performance and reliability. Manufacturers must invest in preventive maintenance programs, spare parts inventory management, and technical support services to minimize downtime and maximize equipment uptime.

Ethical and Social Implications

The widespread adoption of automation raises ethical and social concerns related to job displacement, economic inequality, and the future of work. Policymakers, industry stakeholders, and society must address these challenges proactively and foster inclusive growth and prosperity.

Conclusion

In conclusion, automation is revolutionizing the manufacturing industry, reshaping how goods are produced, and challenging traditional paradigms of labor and production. By embracing automation, manufacturers can unlock new levels of productivity, efficiency, and innovation while addressing the evolving needs of customers and markets. However, the journey towards automation requires strategic planning, investment, and collaboration to navigate challenges and seize opportunities in the digital age. As the world embarks on this journey, they embrace the power of automation to build a more sustainable, inclusive, and prosperous future for all.

Recent Comments